In today’s rapidly evolving manufacturing landscape, energy efficiency is a critical concern. As industries seek to reduce their carbon footprint and operational costs, the production of energy-efficient parts has become paramount. One technology that has played a pivotal role in achieving this goal is Computer Numerical Control (CNC) machining. This article explores how CNC machining has revolutionized the process of designing and producing energy-efficient parts.

The CNC Machining Revolution

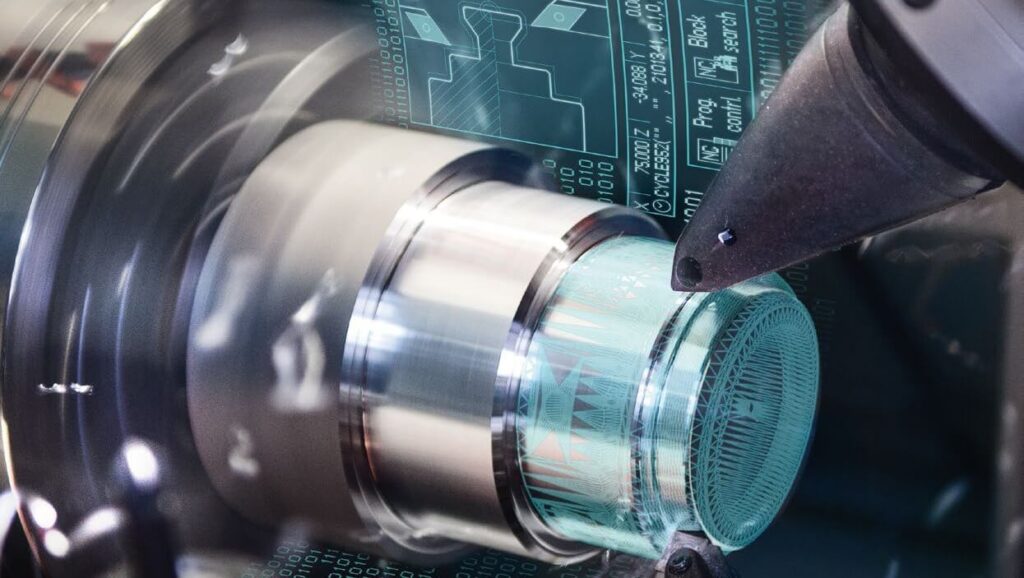

CNC machining has emerged as a game-changer in the world of manufacturing. Unlike traditional manual machining processes, CNC machining relies on computer-aided design (CAD) software and computer-controlled machinery to produce intricate and precise parts. This technology has significantly improved the accuracy, speed, and repeatability of manufacturing processes across various industries.

Design Optimization

The journey towards energy-efficient parts begins with the design phase. CNC machining allows engineers and designers to create complex and highly customized components that maximize energy efficiency. By leveraging CAD software, designers can optimize the shape, size, and material selection of parts to minimize wind turbine machining and energy consumption.

Material Selection

CNC machining enables the use of lightweight and high-strength materials that are essential for energy-efficient applications. By choosing the right material, designers can reduce the overall weight of components, resulting in improved fuel efficiency and reduced energy consumption in various applications such as automotive, aerospace, and renewable energy.

Precision and Tight Tolerances

One of the key advantages of CNC machining is its ability to produce parts with tight tolerances. Energy-efficient systems often require components to fit together seamlessly to minimize energy loss. CNC machining ensures that each part is manufactured to exact specifications, reducing the need for additional adjustments and improving overall system performance.

Reduced Waste

Traditional manufacturing methods often generate significant waste due to material removal processes. In contrast, CNC machining is a subtractive manufacturing technique that minimizes waste by precisely cutting material to create the desired shape. This reduction in waste not only conserves resources but also leads to energy savings during material processing.

Energy-Efficient Tooling

CNC machining has evolved to include energy-efficient tooling options. Modern CNC machines are designed with energy-saving features such as variable-frequency drives (VFDs) that optimize power usage based on machining requirements. Additionally, the use of high-efficiency cutting tools and cooling systems helps reduce energy consumption during the machining process.

Automation and Energy Conservation

CNC machining is often integrated into automated production lines, allowing for continuous and efficient manufacturing. Automation minimizes idle time, optimizes toolpath planning, and reduces human error. As a result, energy is conserved by maximizing machine uptime and minimizing resource wastage.

Sustainable Practices

The shift towards sustainable manufacturing practices aligns with the production of energy-efficient parts. CNC machining contributes to sustainability by reducing the environmental impact of manufacturing operations. Lower energy consumption, reduced waste, and optimized material usage all contribute to a greener and more sustainable manufacturing ecosystem.

Conclusion

CNC machining has revolutionized the way energy-efficient parts are designed and produced. From optimizing material selection to achieving precise tolerances and reducing waste, CNC machining plays a pivotal role in the creation of components that are essential for energy-efficient systems. As industries continue to prioritize sustainability and energy efficiency, CNC machining will remain a critical tool in their quest to create a more environmentally friendly and cost-effective future.