In today’s rapidly evolving manufacturing landscape, precision is not just a goal—it’s a necessity. But how do CNC machine companies achieve the kind of precision that modern manufacturing demands? The answer lies in advanced technologies like Coordinate Measuring Machines (CMM). These machines are transforming the way CNC machine companies operate, pushing the boundaries of what’s possible in production. But what exactly makes CMM technology so impactful? Let’s explore how CNC machine companies are elevating manufacturing through the power of CMM.

Precision Boosters for Flawless Production

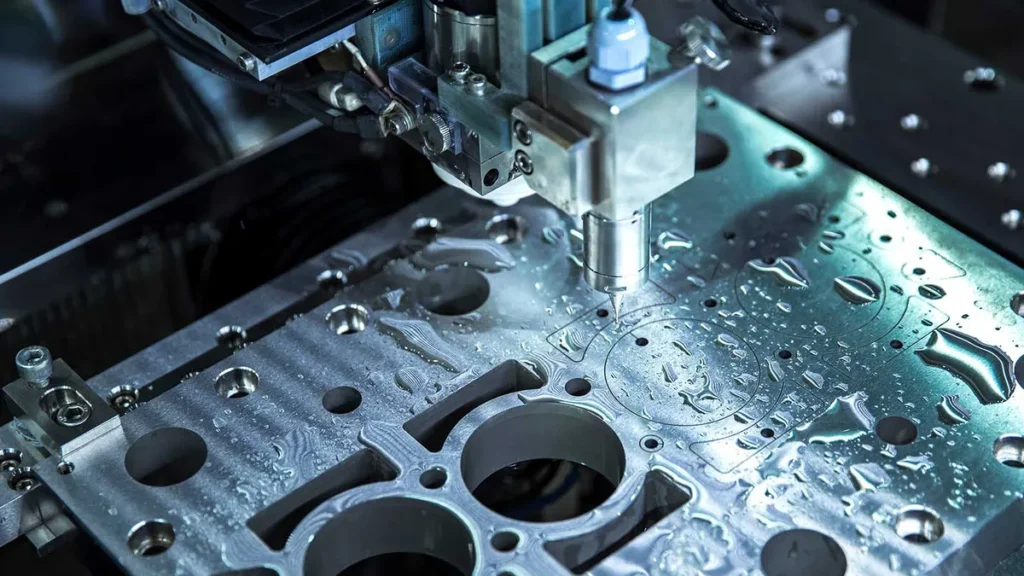

CNC machine company understand that precision is the foundation of flawless production. But achieving this level of accuracy is no small feat. This is where CMM technology comes into play. By integrating CMM machines into their production processes, CNC companies can measure complex geometries with pinpoint accuracy, ensuring that every part meets the exact specifications required.

The use of CMM technology allows for the detection of even the slightest deviations in a part’s dimensions. This capability is crucial for industries where precision is paramount, such as aerospace and automotive manufacturing. With CMM machines, CNC machine companies can boost precision to new heights, reducing the likelihood of errors and enhancing overall product quality.

Innovators in Dimensional Accuracy

Dimensional accuracy is at the core of high-quality manufacturing. CNC machine companies that utilize CMM technology are at the forefront of innovation in this area. CMM machines are designed to measure the geometry of physical objects with a high degree of accuracy, making them indispensable tools for CNC companies striving to achieve perfect dimensional accuracy.

These machines use advanced probing systems to capture precise measurements, allowing CNC companies to verify that every part conforms to the desired specifications. By incorporating CMM technology into their operations, CNC machine companies are not just maintaining standards—they are setting new ones, leading the way in dimensional accuracy.

Streamlining Quality Control with Speed

Quality control is a critical aspect of manufacturing, and speed is often of the essence. CNC machine companies that embrace CMM technology are able to streamline their quality control processes without compromising accuracy. CMM machines offer rapid measurement capabilities, enabling quick inspections that help maintain a fast-paced production environment.

This speed is particularly beneficial in industries where time-to-market is a competitive factor. By reducing the time spent on quality checks, CNC machine companies can increase their production throughput while ensuring that every product meets the highest standards. CMM technology allows for efficient quality control, marrying speed with precision.

Leaders in Reducing Production Errors

Production errors can be costly, both in terms of time and resources. CNC machine companies are leading the charge in reducing these errors by leveraging CMM technology. The accuracy provided by CMM machines minimizes the risk of defects, ensuring that each part is produced correctly the first time.

By incorporating CMM machines into their workflows, CNC companies can detect and correct potential issues early in the production process. This proactive approach to quality control significantly reduces the likelihood of errors reaching the final product, saving time and resources while maintaining high standards of quality. CNC machine companies that utilize CMM technology are true leaders in error reduction.

Champions of Consistent Manufacturing Output

Consistency is key in manufacturing, and CNC machine companies that use CMM technology are champions in maintaining consistent output. CMM machines provide reliable, repeatable measurements that ensure every part produced is identical in quality and dimensions. This consistency is vital for maintaining customer satisfaction and meeting industry standards.

The ability to produce consistent, high-quality parts is a hallmark of top-tier CNC machine companies. By integrating CMM technology, these companies can deliver uniform products across large production runs, ensuring that every item meets the same high standards. This consistency in manufacturing output is what sets CNC machine companies apart in a competitive market.

Pioneers in Advanced Measurement Integration

CNC machine companies are not just users of CMM technology—they are pioneers in integrating advanced measurement systems into their operations. By seamlessly incorporating CMM machines into their production lines, these companies are able to optimize their workflows and achieve higher levels of efficiency and accuracy.

This integration goes beyond simply adding a machine to the process; it involves the careful coordination of technology and human expertise to create a cohesive manufacturing system. CNC machine companies that lead in advanced measurement integration are at the cutting edge of manufacturing technology, setting the standard for the industry.