HDPE (high-density polyethylene) sheets have many benefits and are used for a wide variety of applications. These include: low moisture absorption, chemical and corrosion resistance, and durability. They are also harder than low-density polyethylene (LDPE), which makes them better for many applications. This article will discuss some of the top benefits of HDPE sheets, and help you decide if it is right for your project.

Durability

HDPE sheets are commonly used in a variety of industries, including food packaging, construction, and manufacturing. These properties make them a preferred choice in marine applications. Here are some factors to consider when evaluating the durability of hdpe sheets for marine applications.

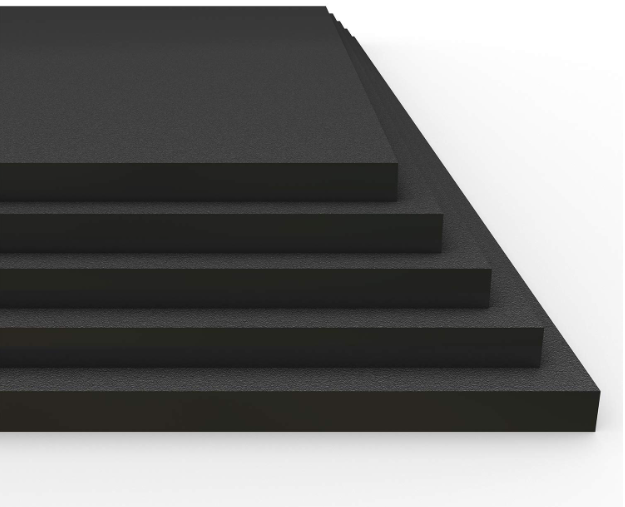

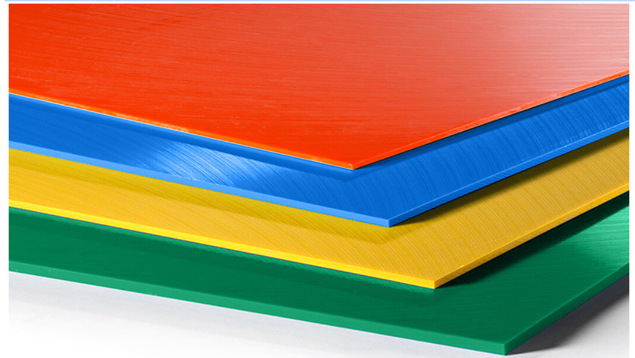

High-density polyethylene (HDPE) is a strong, lightweight plastic material commonly used in building materials. It’s tough and cutting-down properties make it an excellent choice for packaging products. There are two main types of HDPE sheets: textured and smooth. Both types are FDA-approved for food contact. HDPE sheets are very strong and durable and are used in many applications for marine environments. These sheets have many advantages, including being lightweight, easy to work with, and abrasion-resistant.

In addition to being antibacterial, HDPE sheets can resist stain-causing bacteria, algae, and fungi. Antimicrobial properties make them ideal for marine environments and can be fabricated easily using standard woodworking tools. King MicroShield(tm) antimicrobial additive is available for HDPE sheets that are prone to odor. These sheets can also be fabricated to simulate wood and metal, allowing users to make attractive and durable products.

One of the most common methods of testing the quality of HDPE sheet is the HDPE U-shaped specimen test. This method requires a U-shaped specimen containing HDPE resins to be placed in a wetting agent at 50 degrees C. The length of time required for the specimen to break is then measured. This method creates tensile stress on the outer radius of the bend, which will eventually relax over a period of time. By 100 hours, the specimen no longer shows any signs of tension in the specimen.

Resistant to chemicals

HDPE sheets are a versatile plastic, as they can resist a variety of chemical agents. These features are important in packaging, but their primary benefits extend beyond their ability to resist chemicals. They have excellent fatigue and heat resistance, and can also be recycled for their environmental benefits. Plus, they are highly resistant to acids, alcohols, and basic solvents, making them suitable for a variety of industries. And since they are non-toxic, HDPE sheets are recyclable.

HDPE is also naturally resistant to mold, mildew, and insect infestation. And because HDPE is naturally resistant to chemicals, it’s safer to use than traditional wood. Its natural chemical resistance also makes it ideal for outdoor applications, including construction and landscaping projects. Plus, HDPE sheets are also easy to clean and don’t require a lot of maintenance. Simply wipe them down with water to remove any dirt or grime.

HDPE sheets have many benefits over traditional wood. Regular wood usually succumbs to wood-rot, and they don’t require additional finishes. The malleability of HDPE makes them the ideal choice for any type of application. They’re easily cut and molded to fit any size and shape, giving them an unmatched degree of versatility. If you’re building a dock, HDPE sheets are a great choice.

High-density polyethylene is a thermoplastic material derived from petroleum. It has high impact strength and low coefficient of friction. It’s also BPA-free, recyclable, and affordable. It’s no wonder that HDPE is a popular choice for many manufacturers and designers. These sheets are durable, versatile, and chemical-resistant. A number of other advantages make HDPE sheets a great choice for a variety of applications.

Non-porous

Porex offers sintered porous plastic sheets that come in a variety of thicknesses and materials. These sheets are hydrophilic and are commonly used for filtering and diffusing fluids. In addition, they are durable and resistant to most chemicals. Porex porous plastic sheets can also be cut into any 2D geometric shape. Porex also offers rods made of these porous plastics in a variety of porosities.

Compared to other polyethylene sheet products, HDPE is durable and has low cost. This makes it ideal for a variety of applications. The material is also resistant to chemicals and corrosion, and it has a low coefficient of friction. It is easy to cut, weld, thermoform, and engrave. Its properties make it ideal for construction and industrial applications. And if you’re looking for a plastic cutting board, don’t worry, Alibaba offers custom plastic cutting boards and more.